The failure of gas turbine components can often result from high temperature oxidation, erosion, corrosion or a combination of these. To allow higher performance and longer life for these high cost, critical components they require additional protection due to the temperatures, stresses and wear that they encounter in their daily use. ATL offers several different coating options to protect parts and extend their operating envelope and lifecycle.

Protective Coatings

Our Customers

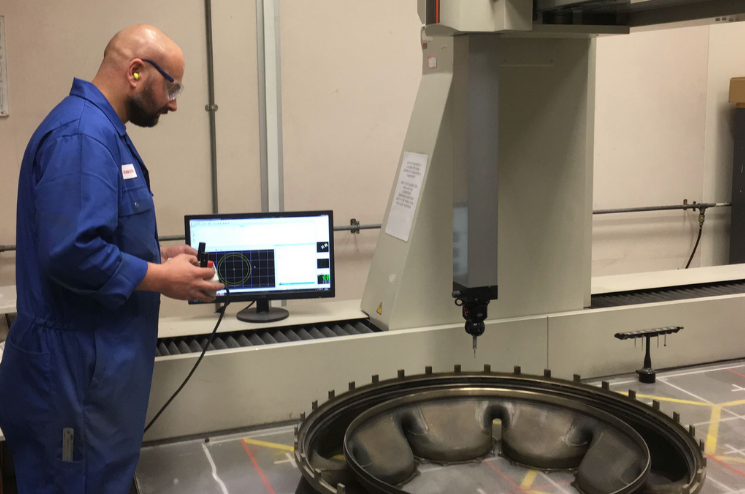

ATL has supplied coating solutions for over 25 years for some of the most demanding clients in the Aerospace industry. In an application where the performance and longevity of hot section parts is reliant on the quality of the coatings, ATL is approved by some of the largest companies in this sector.We can support a vast range of critical parts, including turbine blades, nozzle guide vanes and turbine discs, stator vanes, castings, seal segments, shafts and combustion hardware.

OUR PROTECTIVE COATING SERVICES INCLUDE:

Diffused Aluminide

Wear Resistant Coatings

Robotic High Velocity Oxy Fuel (HVOF)

Robotic Air Plasma

NiCoCrAlY

CoNiCrAlY

MCrAlY Metallic Coating By Robotic HVOF

Ceramic Thermal Barrier Coating

To find out more about our protective coating services and how they could benefit your needs, please contact us.