To save our customers valuable time and resource, ATL actively encourages our customers to send us their components in a ‘ship dirty’ condition. Whatever components arrive with us we will always inspect them on arrival and having a customer inspect then prior to sending is effectively ‘double inspection’ and leads to additional cost and time that can be used to better effect.On receipt of your parts, we will clean, NDT, inspect and report on their condition. You will then receive a comprehensive condition assessment report detailing exactly what is required to return your components to a serviceable function. At this point you can decide to progress a repair or seek an alternative.

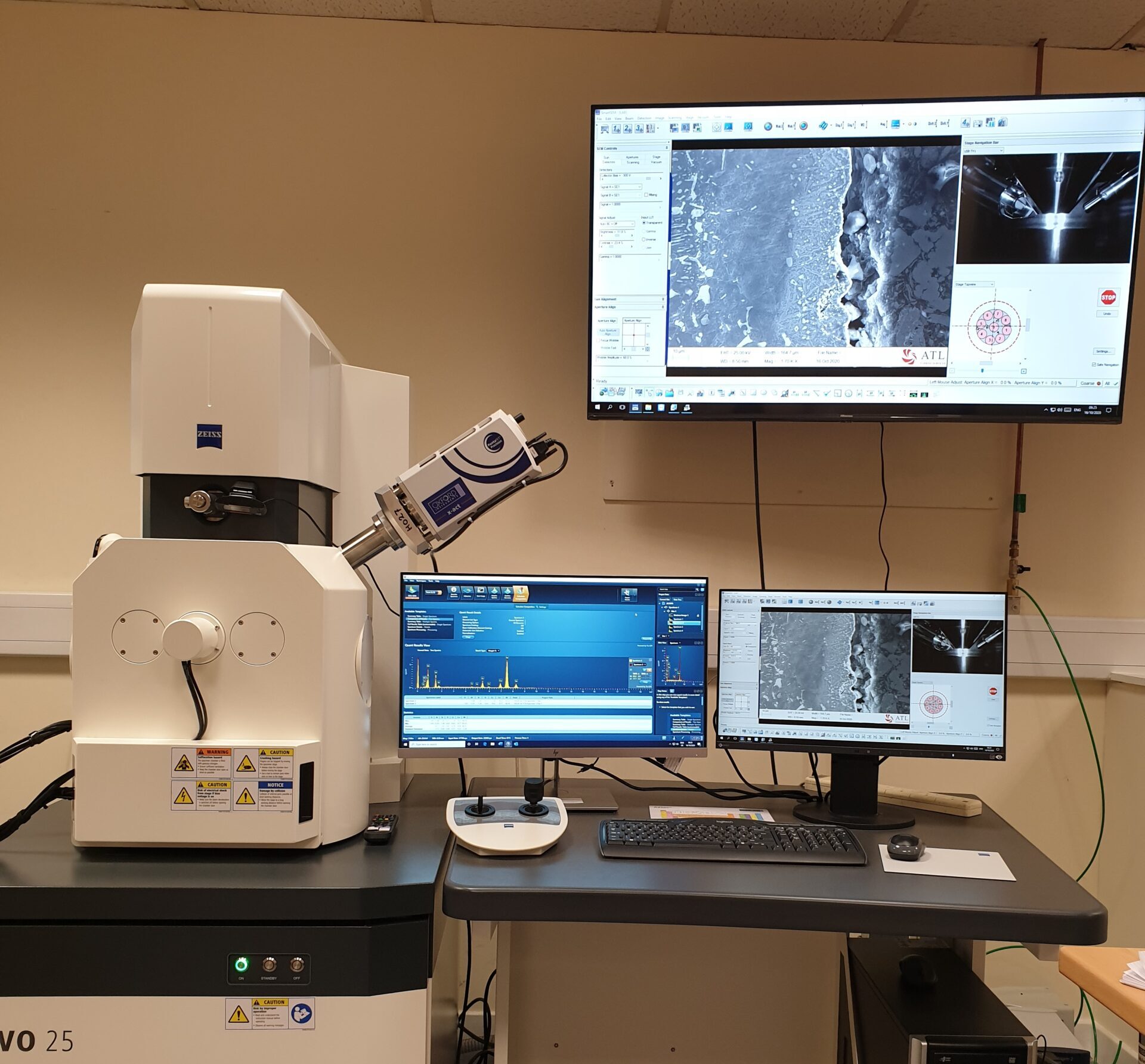

Laboratory Analysis

Scanning Electron Microscopy, or SEM analysis, provides high-resolution imaging for evaluating materials for surface fractures, flaws, contaminants or corrosion. Through SEM, our metallurgical experts provide a thorough examination of material properties and provide valuable insights on the material condition and their parts.

This analysis is multi-faceted and can be a critical aspect to an investigation of a failed part, to determine component life, and to support new repair development and life extension repairs. Typical uses for SEM are:

· Particle Analysis

· Surface Flaw/Defect Analysis

· Contaminant & Residue Analysis

· Failure Analysis & Investigation

· Fractography

OUR CONDITION ASSESSMENT SERVICES:

To find out more about our condition assessment services and how they could benefit your needs, please contact us.

Automated Component Cleaning

Coating Removal

Mechanical Stripping

Chemical Stripping

Visual, Dimensional & Non-destructive Inspection Techniques

Metallurgical Evaluation

Metallurgical Evaluation

Material Identification

Condition Assessment

Failure Analysis

Residual Life Determination

Rejuvenation Process Selection