Assessment

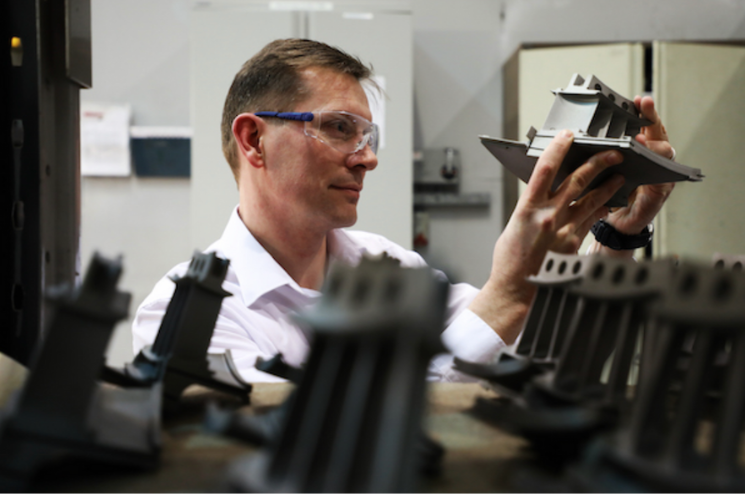

To save valuable time and resource, ATL receives components in a ‘ship dirty’ condition. On receipt of your parts, we clean, NDT, inspect and report on their condition. You will then receive a comprehensive assessment report detailing exactly what is required to return your components to a serviceable status. At this point you can decide to progress a repair or seek an alternative.

ATL can also undertake a higher level of component condition analysis through our in-house laboratory using Scanning Electron Microscopy (SEM). SEM delivers high-resolution imaging for evaluating materials for surface fractures, flaws, contaminants or corrosion.

Through SEM, our metallurgical experts can provide a thorough examination of material properties and provide valuable insights on the material condition. This analysis can be a critical aspect to an investigation of a failed part, to determine component life, and to support new repair development and life extension repairs.

Our Assessment Services

Automated Component Cleaning

Coating Removal

Mechanical Stripping

Chemical Stripping

Metallurgical Evaluation

Material Identification

Condition Assessment

Rejuvenation Process Selection

More Capabilities