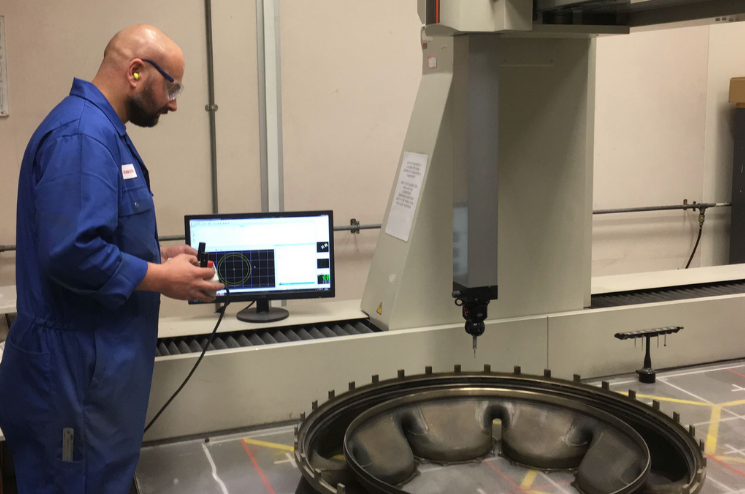

Laboratory Services

The ATL laboratory monitors and checks many aspects of our internal operations, from chemical tank, legionella and coating testing through to material identifications. The laboratory is a critical part in assuring the product safety and quality that ATL supplies.

Our laboratory also undertakes external services for customers across a variety of industry sectors who require external analysis or validation of their own testing. These services generally involve metallurgical analysis and include:

Metallurgical Preparation

Preparing samples for testing is a fundamental part of delivering an accurate test result.

- Our lab has all the required equipment to section, mount and polish samples prior to analysis.

- Chemical etching is used as part of a metallographic analysis or as a pre-NDT check. This technique removes the top layer of material to allow a better view of the crystalline structure of the alloy.

Life Analysis / Grain Structure Analysis

Techniques here are used to determine if a part can go through the repair process or if it needs to be retired from service.

-

- SEM microscopy

– Material identification

– Failure analysis - Optical microscopy

- Coating assessments

– Diffused coatings

– Thermal barrier coatings - Welding assessment

- Braze assessment

- Hardness testing

- Part repair recommendations

- SEM microscopy

Whatever your industry and whatever your metallurgical testing requirements are, ATL’s laboratory analysis services can help give you the third-party check and/or confidence you need to clearly understand the condition of your parts.

Our team will work with you to define your requirements, set out a scope and analysis regime and then undertake the work for you, delivering a comprehensive report of our findings.

The ATL laboratory monitors and checks many aspects of our internal operations, from chemical tank, legionella and coating testing through to material identifications. The laboratory is a critical part in assuring the product safety and quality that ATL supplies.

Our laboratory also undertakes external services for customers across a variety of industry sectors who require external analysis or validation of their own testing. These services generally involve metallurgical analysis and include:

Metallurgical Preparation

Preparing samples for testing is a fundamental part of delivering an accurate test result.

- Our lab has all the required equipment to section, mount and polish samples prior to analysis.

- Chemical etching is used as part of a metallographic analysis or as a pre-NDT check. This technique removes the top layer of material to allow a better view of the crystalline structure of the alloy.

Life Analysis / Grain Structure Analysis

Techniques here are used to determine if a part can go through the repair process or if it needs to be retired from service.

-

- SEM microscopy

– Material identification

– Failure analysis - Optical microscopy

- Coating assessments

– Diffused coatings

– Thermal barrier coatings - Welding assessment

- Braze assessment

- Hardness testing

- Part repair recommendations

- SEM microscopy

Whatever your industry and whatever your metallurgical testing requirements are, ATL’s laboratory analysis services can help give you the third-party check and/or confidence you need to clearly understand the condition of your parts.

Our team will work with you to define your requirements, set out a scope and analysis regime and then undertake the work for you, delivering a comprehensive report of our findings.

Our Services

Metallurgical Evaluation

Material Identification

Condition Assessment

Failure Analysis

Residual Life Determination

Rejuvenation Process Selection

Root Cause Analysis & Recommendations

More Capabilities